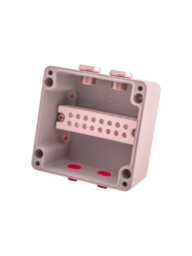

Rugged GRP Enclosure

Glass Reinforced Polyester is highly resistant to contamination from oils, fats, industrial compounds, bacteria and enzymes. This makes GRP an ideal material for electrical junction boxes used for industrial process equipment.

The BPG is comprised of 16 enclosure sizes. The range is moulded from SMC sheet material rather than short stranded DMC, the results are much greater mechanical strength and resistance to UV. Also increased performance in the event of the enclosure being exposed to extreme heat and flames.

The BPG junction box has excellent ingress protection qualities (IP66/67 and Type 4X) due to the enclosure’s labyrinth seal system, whereby the seal is protected from the external environment. The mounting holes, although contained within the profile of the enclosure, are also designed to sit outside the seal maintaining its integrity.

Designed for maximum flexibility. Entries can be drilled on any of the four sides, even on the back. The enclosure itself can be uniquely customised with the addition of internal/external earth studs, earth continuity plates or earth bars. A mounting plate can also be added to accommodate non-rail mounted components.

The BPG enclosure is fire rated. It provides PH120 insulation integrity in accordance with BS EN 50200 when fitted with suitable heat resistant internal components and terminals.

the bpg range

-

Highly resistant to chemicals and ultraviolet rays

-

IP66/67 and Type 4X for maximum ingress protection

-

Entries can be drilled on any face

STANDARD SIZES

| Product Reference | Width (mm) | Height (mm) | Depth (mm) | Weight (KG) |

|---|---|---|---|---|

| EBPG06 | 122 | 120 | 90 | 0.75 |

| EBPG07 | 220 | 120 | 90 | 1.0 |

| EBPG08 | 160 | 160 | 90 | 1.0 |

| EBPG09 | 260 | 160 | 90 | 1.17 |

| EBPG10 | 360 | 160 | 90 | 2.15 |

| EBPG11 | 560 | 160 | 90 | 3.2 |

| EBPG12 | 255 | 250 | 120 | 3.2 |

| EBPG13 | 400 | 250 | 120 | 3.65 |

| EBPG13.5 | 400 | 250 | 160 | 4.87 |

| EBPG14 | 600 | 250 | 120 | 2.25 |

| EBPG15 | 400 | 405 | 120 | 5.58 |

Note: Sizes smaller than a BPG06 are available, please refer to datasheet.